| Size |

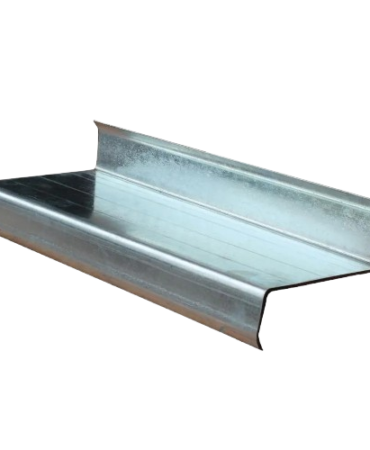

10" x 3" x 1.6mm, 10" x 3" x 2.0mm, 10" x 3" x 2.5mm, 10" x 3" x 3.0mm, 4" x 2" x 1.6mm, 4" x 2" x 2.0mm, 4" x 2" x 2.5mm, 4" x 2" x 3.0mm, 6" x 2.5" x 1.6mm, 6" x 2.5" x 2.0mm, 6” x 2.5” x 2.5mm, 6” x 2.5” x 3.0mm, 8" x 3" x 1.6mm, 8" x 3" x 2.0mm, 8" x 3" x 2.5mm, 8" x 3" x 3.0mm

|

| Precautions |

Material Handling and Storage

Handle Carefully: Purlins, especially metal ones like steel and aluminum, should be handled carefully to avoid bending, warping, or damaging their protective coatings (e.g., galvanized layers). Mishandling during transportation or installation can weaken them structurally.

Store Properly: Store purlins in a dry, covered area before installation to protect them from moisture, which could lead to rust or swelling (in the case of wooden purlins). Storing them horizontally, off the ground, and with supports can help prevent bending or damage.

Protect Coatings: Galvanized or coated purlins should be kept free from scratches or dents, as this can expose the base metal to corrosion.

Correct Alignment and Spacing

Ensure Proper Alignment: During installation, ensure that purlins are aligned according to design specifications. Misalignment can cause improper load distribution, leading to structural failure.

Follow Spacing Guidelines: Install purlins according to the recommended spacing. Incorrect spacing can result in roof sagging or overloading of individual purlins. String lines or laser levels can be helpful for ensuring correct spacing and alignment.

Thermal Expansion Considerations: Allow for slight movement due to thermal expansion and contraction, particularly with metal purlins. Ensure slotted holes or expansion joints are used to accommodate this movement without stressing the purlins.

Fastening and Fixing

Use Appropriate Fasteners: Ensure that proper fasteners are used for the specific material. For example, stainless steel fasteners for steel purlins and corrosion-resistant fasteners in environments prone to moisture or chemicals. Follow the manufacturer’s guidelines for clip-lock or bolt systems.

Avoid Over-Tightening: Do not over-tighten fasteners as it can distort the purlin’s shape or damage its surface. Fasteners should be tight enough to secure the purlins but not so tight that they damage the structure.

Secure Clipping Systems: If installing clip-lock systems, ensure that all clips are correctly fastened to prevent purlin movement or shifting over time.

Corrosion Protection During Installation

Seal Exposed Edges: If purlins are cut to size on-site, seal any exposed steel edges with anti-corrosion paint or sealant to protect against rust.

Avoid Dissimilar Metals: When installing purlins in combination with other metals, prevent galvanic corrosion by using isolating gaskets or barriers between dissimilar metals, such as steel and aluminum.

|